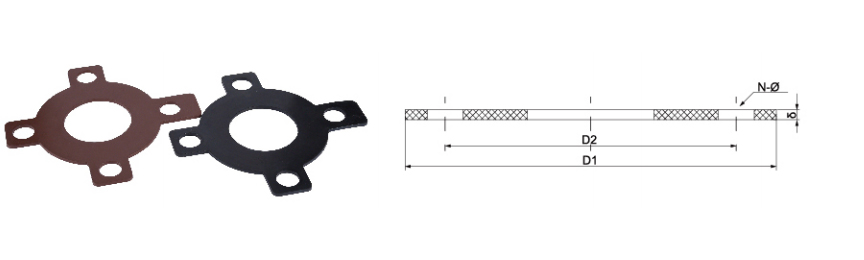

How to choose UPVC/CPVC flange gaskets correctly? Guide to materials, sizes and media compatibility

UPVC (unplasticized polyvinyl chloride) and CPVC (chlorinated polyvinyl chloride) flange gaskets are widely used in many industries due to their excellent corrosion resistance, chemical stability and cost-effectiveness. The correct selection of gaskets requires comprehensive consideration of material properties, size matching and media compatibility to ensure sealing reliability and system safety. The following are key selection points and industry application analysis:

1. Material selection: UPVC vs. CPVC

UPVC: Suitable for normal temperature (0°C~60°C) and low pressure scenarios, with excellent acid and alkali resistance, but poor temperature resistance. Commonly used in pure water delivery systems in the drinking water (Safe Drinking Water), industrial water treatment (Industrial Water Treatment) and electronic semiconductor (Electronic Semiconductor) industries.

CPVC: High temperature resistance (up to 93°C or even higher), higher compressive strength, suitable for high temperature corrosive media. Widely used in pickling process of photovoltaic industry, waste acid recovery of metallurgy, and auxiliary cooling system of nuclear power plant.

2. Size and structure matching

Flange standard: Make sure that the gasket size matches the flange standard (such as ANSI, DIN, JIS) to avoid leakage due to tolerance.

Sealing surface type: Flat flange (FF) often uses rubber gaskets, and convex flange (RF) needs to be matched with gaskets with inner rings, especially in pipelines with high cleanliness requirements in the medicine industry.

3. Key considerations for media compatibility

The fluid media of different industries vary greatly and need to be selected in a targeted manner:

Strong acid/alkali environment (such as industrial wastewater treatment): CPVC is preferred, which is resistant to corrosion such as hydrofluoric acid and concentrated sulfuric acid.

High-purity water/ultrapure water (such as electronic semiconductors): UPVC gaskets must be free of precipitates to avoid water pollution.

Oxidizing media (such as etching solution in the photovoltaic industry): CPVC has better oxidation resistance than UPVC.

High-temperature and high-pressure water vapor (such as auxiliary systems of nuclear power plants): CPVC gaskets must pass pressure resistance and aging resistance tests.

4. Examples of industry application scenarios

Drinking Water: UPVC gaskets comply with FDA/NSF standards to ensure non-toxic and odorless.

Medicine: High-purity CPVC gaskets that withstand CIP/SIP cleaning processes.

Metallurgy: CPVC resists corrosion from smelting waste acids (such as hydrochloric acid and nitric acid).

5. Precautions

Installation preload: Avoid excessive compression that may cause cracking of UPVC/CPVC gaskets.

Thermal expansion compensation: Thermal displacement margins must be reserved for high-temperature conditions (such as photovoltaic or nuclear energy).

+86-15258772971

+86-15258772971

dinys009@163.com

dinys009@163.com